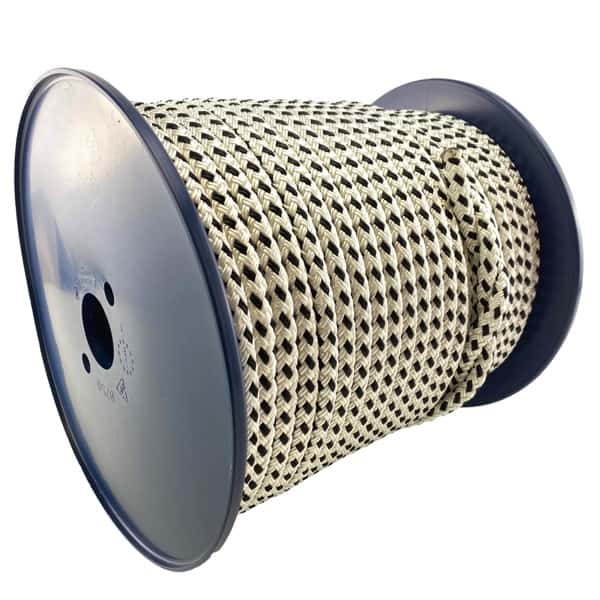

20mm White With Black Fleck Double Braid Polyester Rope (By The Metre)

- Rope Type – Double Braided Polyester

- Colour – White With Black Fleck

- Diameter – 20mm

- Order – By The Metre

- Both Ends Will Be Heat Sealed To Prevent Fraying

- Maximum Continuous Length – 100 Metres

Use the quantity box to indicate how many meters you need. For example, if you require 15 meters, input ’15’ as the quantity.

Should you require the cutting of your rope, please kindly indicate this by leaving a message during checkout. Please be aware that our rope cutting services are limited to the nearest meter, and there may be a fee associated with this service. If you require more precise cutting services, we invite you to contact us directly to discuss your specific needs.

£3.65

20mm White With Black Fleck Double Braid Polyester Rope (By The Metre)

Looking for strong, weather-resistant rope sold by the metre? Our 20mm White With Black Fleck Double Braid Polyester Rope is a high-quality, low-stretch rope ideal for marine, outdoor, and general-purpose use.

Made from 100% polyester, this 20mm double braid rope combines strength and flexibility with a smooth, professional finish. It’s perfect for everything from sailing and camping to pet leads and decorative projects.

Key Features of 20mm White With Black Fleck Double Braid Polyester Rope:

-

Diameter: 20mm

-

Colour: White With Black Fleck

-

Material: Double-braided polyester (braided core and outer sheath)

-

Sold by the metre – choose exactly the length you need

-

Easy to handle and splice

Benefits of Using Polyester Double Braid Rope

-

Low stretch – keeps tension and shape under load

-

UV resistant – ideal for long-term outdoor use

-

Rot and mildew resistant – performs well in wet conditions

-

Smooth finish – easy to knot, coil, and feed through pulleys

This White With Black Fleck double braid rope is a popular choice for boat lines, flagpoles, tent lines, and other outdoor or DIY applications. Its neat appearance and excellent handling also make it great for craft and decorative use.

| Diameter | Max Length Per Reel | Approx Weight Per Reel | Approx Breaking Load |

|---|---|---|---|

| 6mm | 100 Metres | 4.5kg | 680kg |

| 8mm | 100 Metres | 5.6kg | 2,100kg |

| 10mm | 100 Metres | 6.6kg | 2,243kg |

| 12mm | 100 Metres | 10.5kg | 2,957kg |

| 14mm | 100 Metres | 13.3kg | 3,569kg |

| 16mm | 100 Metres | 18.1kg | 4,058kg |

| 18mm | 100 Metres | 21kg | 5,290kg |

| 20mm | 100 Metres | 27kg | 6,420kg |

Please note that all weights and breaking loads provided are approximate. The breaking loads may vary depending on how the rope is finished. It is imperative to subtract 10% from the breaking load for each splice made in the rope. Additionally, please be aware that weights can fluctuate, particularly with natural products, due to differences in manufacturing processes and materials utilised.

Synthetic Rope and Its Properties

Synthetic rope is made from man-made fibers such as nylon, polyester, polypropylene, and polyethylene. These ropes are known for their high strength, durability, and resistance to various environmental factors. Unlike natural ropes, synthetic ropes do not absorb water, making them ideal for use in wet and outdoor environments. However, synthetic ropes have their own set of characteristics and considerations that you should be aware of.

Behavior in Wet Conditions

One of the key advantages of synthetic ropes over natural ones is their minimal water absorption. Synthetic ropes generally do not shrink or expand when exposed to moisture, making them highly reliable in marine, industrial, and outdoor applications. However, while they do not absorb water, some synthetic ropes may become slippery when wet, which can affect handling and knot-holding capabilities.

Effects of UV Exposure

Unlike natural ropes, synthetic ropes are resistant to rot and mildew, but they can be affected by prolonged exposure to UV rays. Over time, UV exposure can weaken the fibers, causing the rope to degrade and lose strength. To mitigate this, synthetic ropes can be treated with UV inhibitors or stored out of direct sunlight when not in use.

Resistance to Chemicals and Abrasion

Synthetic ropes are generally more resistant to chemicals and abrasion compared to natural ropes. For instance, nylon and polyester ropes are highly resistant to various oils, acids, and alkalis, making them suitable for harsh industrial environments. Additionally, these ropes have excellent abrasion resistance, which means they can withstand rough surfaces without significant wear.

Elongation and Stretch

Different types of synthetic ropes have varying degrees of elongation. For example, nylon rope is known for its elasticity, which allows it to absorb shock loads without breaking. This makes nylon rope ideal for dynamic applications such as climbing, towing, and mooring. On the other hand, polyester rope has low stretch, making it suitable for applications where maintaining tension is critical.

Care and Maintenance

To extend the lifespan of synthetic ropes, it’s important to follow proper care and maintenance practices. Regularly inspect the rope for signs of wear, abrasion, or UV damage. If the rope shows significant signs of wear, such as fraying or thinning, it should be replaced to ensure safety and performance.

Storage Considerations

When storing synthetic ropes, keep them in a cool, dry place, away from direct sunlight and chemicals. Coiling the rope properly and avoiding tight bends can also help prevent kinks and maintain the rope’s integrity.

Summary

Synthetic ropes offer numerous advantages over natural ropes, including resistance to water, rot, and chemicals. They are durable and strong, making them suitable for a wide range of applications. However, it’s important to be aware of their susceptibility to UV damage and to take appropriate measures to protect the rope from prolonged exposure. By properly maintaining and storing synthetic ropes, you can ensure their longevity and reliable performance in various conditions.